We get many calls regarding our oil impregnated bearing line. There seems to be some confusion with these products. This post should help you better understand oil impregnated bearings. These bearings are manufactured using the powdered metal process. This process ensures the uniform distribution of pores between the bronze particles which absorbs the oil by capillary action. In addition our bearings have a self-contained oil supply which provides a uniform protective film over the entire bearing surface.

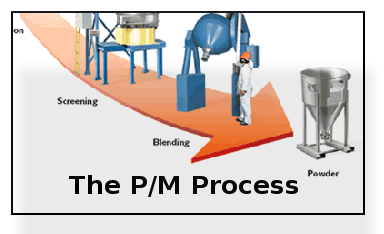

There are several steps involved in how the powdered metal process works, but the end result can be a low-cost, high-quality powdered metal part. Listed below is the typical sintered metal casting process in order:

Blending – This is the process of combining metal powders or alloys together with lubricants to produce a homogeneous mix.

Briquetting – This process is where metal powders or alloys are compressed while restricted in a die, at pressures as low as 10 to 45 tons per square inch.

Sintering – Here each individual particle bonds into a mass. The parts are heated in a protective atmosphere furnace to a high relative temperature below the melting point of the particular metal or alloy.

Repressing – This is the final pressing of a sintered metal part to obtain proper size and physical properties.

Infiltrating – This process fills the pores of a sintered metal part with a metal or alloy of a lower melting point.

Impregnation – This process fills the pores of a sintered metal part with a lubricant.

Heat Treating – This is the heating of a sintered metal part in a protective atmosphere and then oil quenching the part. The results are usually improved strength and hardness.

Machining – If required powdered metal parts can be machined to obtain the desired shape before or after heat-treating is completed.

Understanding the process required to manufacture oil impregnated bearings can help you understand the various limitations of the product. While oil impregnated bearings are not ideal for all situations, they are a great way to go if your requirements permit them.